Discover how Footwearology is at the forefront of footwear innovation using advanced 3D printing technologies and flexible filaments like TPU.

The Vision of Footwearology: Merging Innovation with Sustainability

Footwearology is not just a brand; it’s an innovation lab and academy dedicated to redefining the future of the footwear industry. Based in Barcelona, Spain, Footwearology combines research, consulting, and education to equip professionals with the knowledge and tools needed to embrace advanced manufacturing technologies. Their vision is clear: to transform the global footwear supply chain through sustainable and personalised production methods.

At the heart of Footwearology’s operations lies a commitment to sustainability. By connecting technology providers, designers, and digital platforms, they aim to create a more localised and customised production model. This approach not only reduces waste and transportation emissions but also supports the creation of unique, tailored footwear solutions.

Harnessing the Power of 3D Printing in Footwear Manufacturing

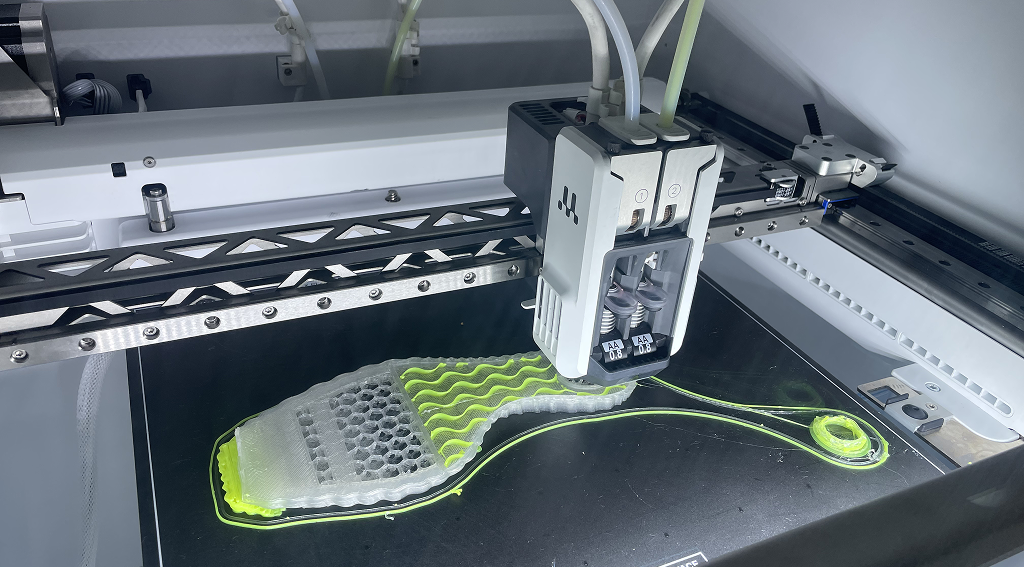

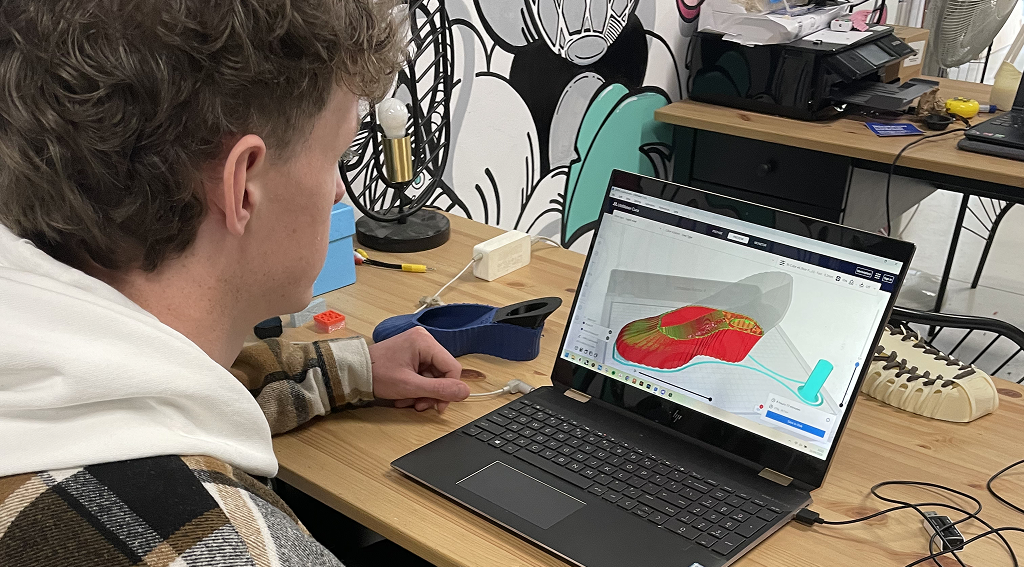

Additive manufacturing, particularly 3D printing, plays a crucial role in Footwearology’s innovative approach. Recognising the potential of 3D printing early on, the team identified Fused Deposition Modelling (FDM) as the most viable technology for scalable, adaptable, and material-efficient production. Unlike traditional prototyping tools, 3D printing is embraced as a full-fledged production technology at Footwearology.

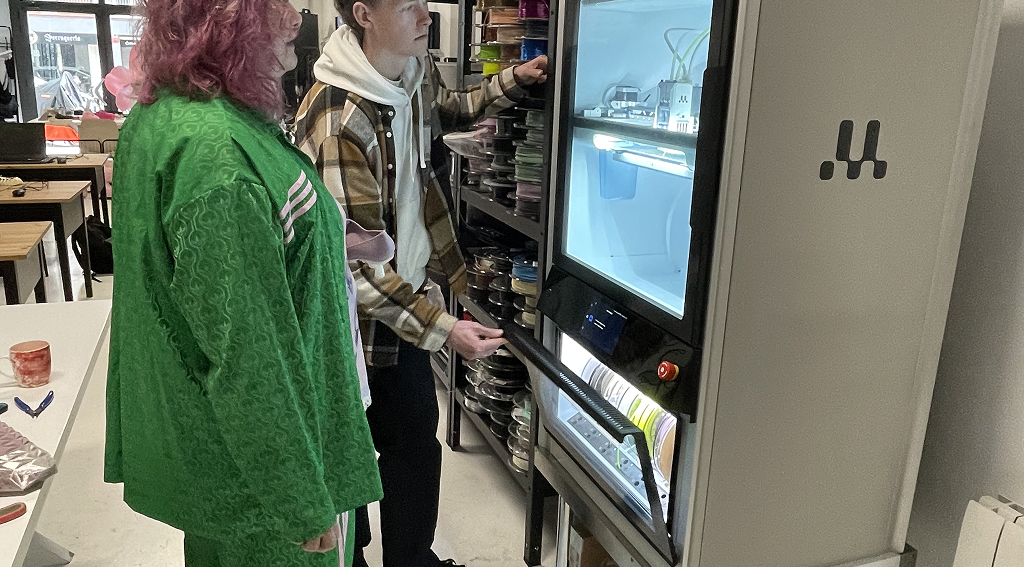

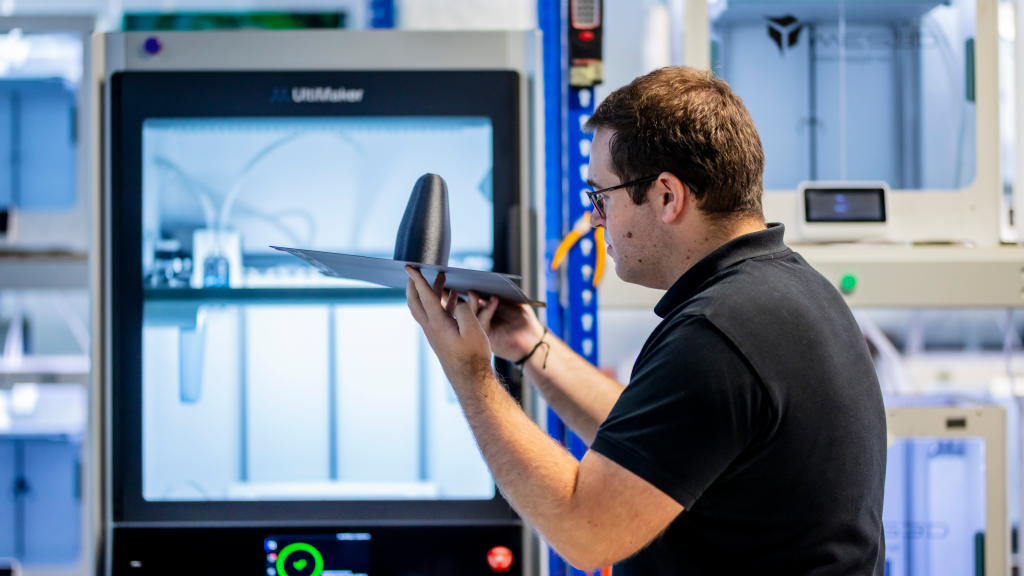

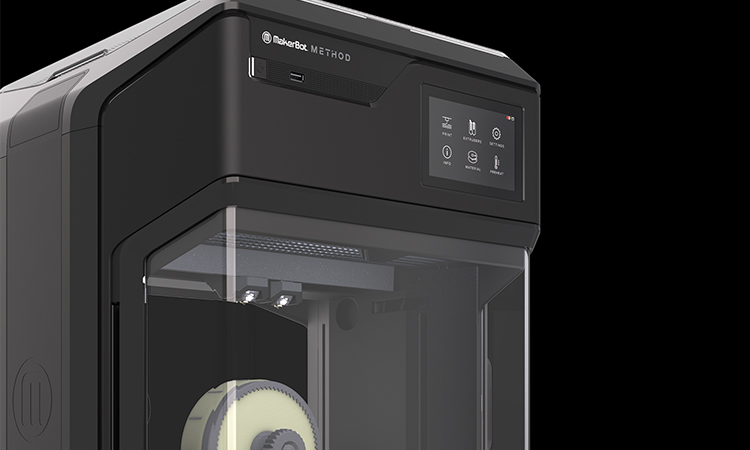

The UltiMaker Factor 4, a high-performance FDM printer, is central to their operations. This industrial-grade printer allows for reliable production with flexible materials like TPU, supporting Footwearology’s goal of developing recyclable and wearable footwear components that meet both functional and environmental standards. By leveraging the power of 3D printing, Footwearology can produce customised footwear components efficiently and sustainably.

The Role of TPU: A Game-Changer in Flexible Filaments

Thermoplastic polyurethane (TPU) is a cornerstone of Footwearology’s material strategy. Known for its durability, flexibility, and recyclability, TPU is particularly well-suited for footwear applications. Footwearology uses TPU to engineer parts with variable stiffness and cushioning, allowing them to meet specific user needs, such as adjusting support based on body weight or gait.

Footwearology collaborates with third-party material manufacturer Recreus to create custom colours for TPU filaments. These filaments come with varied properties, weights, and densities, further enhancing the customisation potential. Prioritising recyclable TPUs, Footwearology is also actively researching compostable alternatives. This focus on material innovation ensures that their products are not only functional and wearable but also environmentally responsible.

UltiMaker Factor 4: Enhancing Precision and Efficiency

After years of experience working with and modifying 3D printers to accommodate flexible materials, Footwearology identified the UltiMaker Factor 4 as the ideal platform for advancing its production capabilities. The Factor 4’s multi-material printing option allows for the printing of entire shoes, making it a versatile solution for complex and high-precision projects.

Key features such as an enclosed build chamber, consistent thermal management, and dual extrusion capabilities make the Factor 4 especially well-suited for printing flexible materials like TPU. The dual gripper direct drive extrusion system ensures a shorter filament path, reducing the risk of material deformation or clogging, common issues when printing with soft materials like TPU. This setup provides extra stability and grip, ensuring consistent material flow even during complex or high-speed prints.

The integration of UltiMaker’s Digital Factory software has also been a game-changer for Footwearology. The software’s capabilities for profile management have streamlined their production, allowing for better scaling and management of multiple printers. This integration optimises material usage, quality, and production speed, enhancing the overall efficiency of their operations.

Decentralised Manufacturing: Reducing Waste and Customising Production

Footwearology’s vision centres on a decentralised “network production” model. This innovative approach involves regional manufacturing hubs producing personalised footwear on a large scale. By decentralising production, Footwearology significantly reduces material waste, transportation emissions, and inventory costs, while supporting customisation based on individual biomechanical profiles.

This model allows for on-demand production, ensuring that each pair of shoes is tailored to the wearer’s specific needs. By leveraging advanced 3D printing technologies and flexible filaments, Footwearology is able to create high-quality, customised footwear efficiently and sustainably. This approach not only benefits the environment but also meets the growing consumer demand for personalised products.

Future Prospects: Bridging Technology and Sustainable Footwear

|

As Footwearology continues to explore the boundaries of digital manufacturing and material science, their focus remains on advancing sustainable, scalable solutions for the footwear industry. Their ongoing partnership with UltiMaker and the use of the Factor 4 are integral to achieving this vision, enabling new levels of customisation, efficiency, and environmental responsibility in footwear design and production. The future of footwear manufacturing lies in the seamless integration of advanced technologies and sustainable practices. |

|

Footwearology’s innovative approach serves as a model for the industry, demonstrating how flexible filaments and 3D printing can revolutionise production processes. By continuing to prioritise sustainability and customisation, Footwearology is paving the way for a more responsible and innovative future in footwear manufacturing.

Are you looking to expand your operations and innovate with 3D printing? Talk to UltiMaker experts today to learn more about the Factor 4 industrial-grade 3D printer and how it can streamline your production processes.