Alloys

How 3D Printing Is Transforming Modern Manufacturing

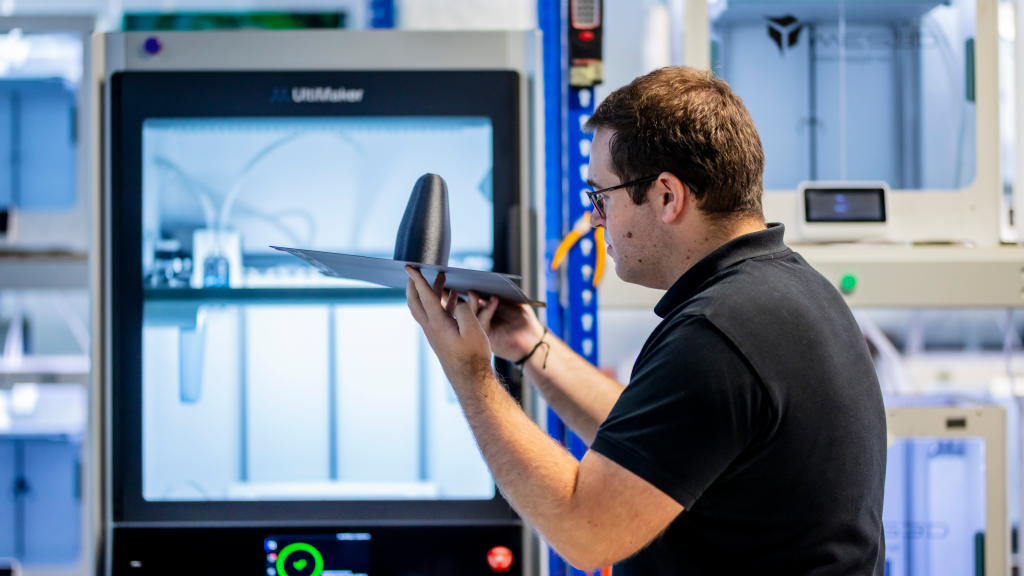

Manufacturing today moves fast, and innovation is essential for staying competitive. 3D printing (additive manufacturing) has become a core technology reshaping how products are designed, produced, and delivered. By enabling complex geometries, rapid iteration, and on-demand production, 3D printing helps manufacturers streamline workflows, cut costs, and accelerate development.

Ultimaker plays a critical role in this transformation. With reliable, industrial-ready 3D printers—including the Ultimaker Factor 4—and powerful software, Ultimaker provides manufacturers with the flexibility and performance needed to meet the evolving demands of modern production environments.

Design Flexibility: Unlocking Complex and Optimised Geometries

One of the biggest advantages of additive manufacturing is design freedom. Traditional manufacturing often limits what designers can create due to tooling restrictions. In contrast, 3D printing allows engineers to produce complex geometries, lightweight structures, and optimised internal shapes that would be impossible or too costly with conventional methods.

Industries such as aerospace and automotive already use this capability to create lighter, more efficient parts. Ultimaker’s ecosystem—including UltiMaker Cura software—supports advanced design workflows, helping users push the boundaries of part complexity, performance, and creativity.

Rapid Prototyping: Faster Product Development Cycles

Speed is essential in highly competitive markets. Rapid prototyping with 3D printing provides a significant advantage by enabling quick production of testable models and functional prototypes. Manufacturers can iterate designs, validate concepts, and refine products in days instead of weeks.

Ultimaker’s S Series printers are specifically designed for rapid prototyping. They allow engineers to accelerate development, reduce time-to-market, and experiment more freely—supporting a more agile and innovative product development process.

Customisation & On-Demand Manufacturing: Meeting Evolving Customer Needs

Today’s customers expect personalised products and flexible production options. 3D printing supports cost-effective customisation and low-volume production without the high tooling costs of traditional manufacturing.

Whether producing customised medical components, personalised consumer products, or tailored industrial tools, manufacturers can easily adjust designs and print parts on demand.

Ultimaker’s wide range of materials and reliable printer lineup supports this shift. With Alloys’ ability to scope and design tailored solutions, businesses can seamlessly integrate Ultimaker systems to meet unique customer requirements efficiently and affordably.

Material Efficiency & Sustainability: Reducing Waste in Manufacturing

Sustainability is a top priority across industries. As an additive process, 3D printing uses only the material required to create a part—significantly reducing waste compared to subtractive manufacturing.

Ultimaker continues to develop sustainable material options, including biodegradable filaments and carbon-reinforced composites designed for industrial use. This combination of performance and sustainability helps manufacturers reduce environmental impact while maintaining strong, reliable part performance.

Ultimaker’s Innovative Solutions for Modern Manufacturing

Ultimaker remains at the forefront of industrial 3D printing, offering tools that support manufacturing excellence. Key advantages include:

-

Factor Series printers for industrial-grade performance

-

Compatibility with 280+ materials

-

Proven reliability for prototyping and production

-

Advanced software and workflow tools

These capabilities make Ultimaker a powerful partner for businesses aiming to expand their additive manufacturing capabilities.

Alloys provides the expertise and support needed to integrate Ultimaker systems into real manufacturing environments—helping companies enhance efficiency, reduce costs, and drive continuous innovation.

Conclusion

3D printing is no longer an optional technology—it is reshaping modern manufacturing. With Ultimaker’s advanced 3D printing solutions and Alloys’ ability to build tailored implementation plans, businesses can unlock new opportunities in design, production, efficiency, and sustainability.

Manufacturers who adopt these technologies today will be better positioned to innovate and compete in tomorrow’s fast-changing industrial landscape.