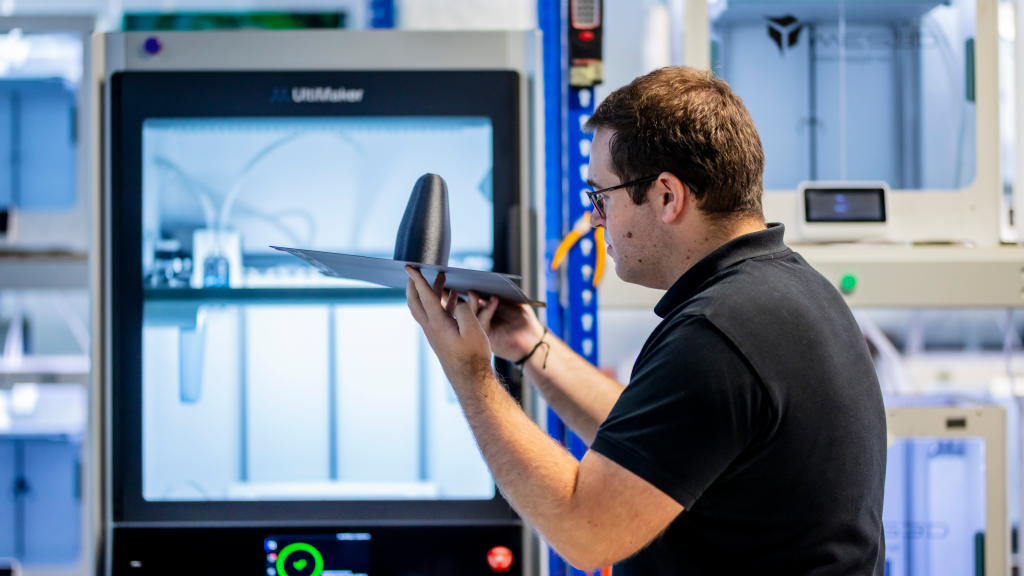

When you're designing premium business-class cabins for global aviation giants like Boeing and Airbus, every iteration counts. Jamco America — a leading aircraft interiors manufacturer — turned to the MakerBot METHOD to speed up prototyping, cut costs, and modernise their workflow.

THE CUSTOMER

Based in Everett, Washington, Jamco America designs and manufactures aircraft seating, cabin furnishings, and retrofit components for major aerospace clients. Their development teams rely heavily on rapid iteration to meet the demands of innovation and tight production schedules.

THE CHALLENGE

Jamco previously depended on industrial 3D printers located at their Tokyo headquarters — with up to one-month lead times.

Local service bureaus weren’t much better, costing hundreds per part with turnaround times stretching into weeks.

A low-cost desktop 3D printer was tested but failed to deliver the accuracy, reliability, and performance needed for aerospace-grade prototyping.

THE SOLUTION

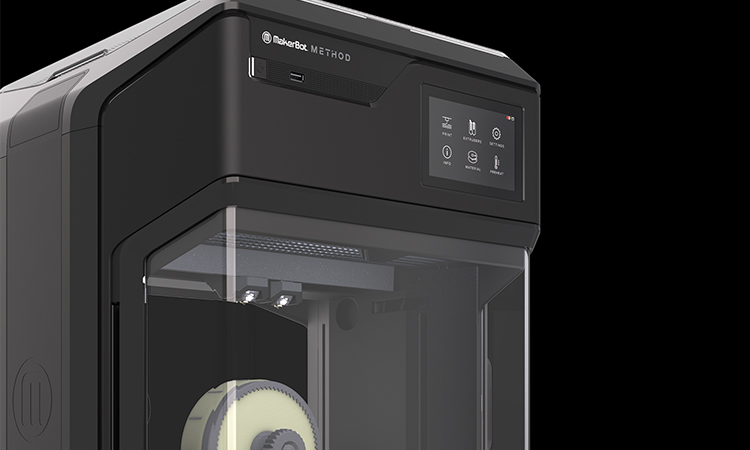

After evaluating 15 different printers, Jamco selected the MakerBot METHOD for its balance of industrial capabilities, cost efficiency, and scalability.

METHOD’s:

-

Circulating Heated Build Chamber

-

PVA water-soluble support material

…enabled Jamco to achieve industrial-level dimensional accuracy and produce complex geometries with confidence.

“METHOD helped us improve our process to meet our goals of rapid prototyping and many iterations, very quickly,” says John Cornell, Manager of Product R&D.

THE PRINTS

With a simple plug-and-play setup, Jamco immediately began printing functional prototypes, including:

-

Crew step ergonomics models

-

Long extrusions up to 48 inches, printed in bonded sections

-

Components tested for spatial usability and structural fit

The difference? Night and day.

|

Outsourced 3D Printing |

METHOD in-house |

|

Total Cost $350 |

$14 |

|

Total Time 30 days |

1 day |

Learn more about METHOD and MakerBot’s full professional 3D printer lineup: www.makerbot3d.com.au