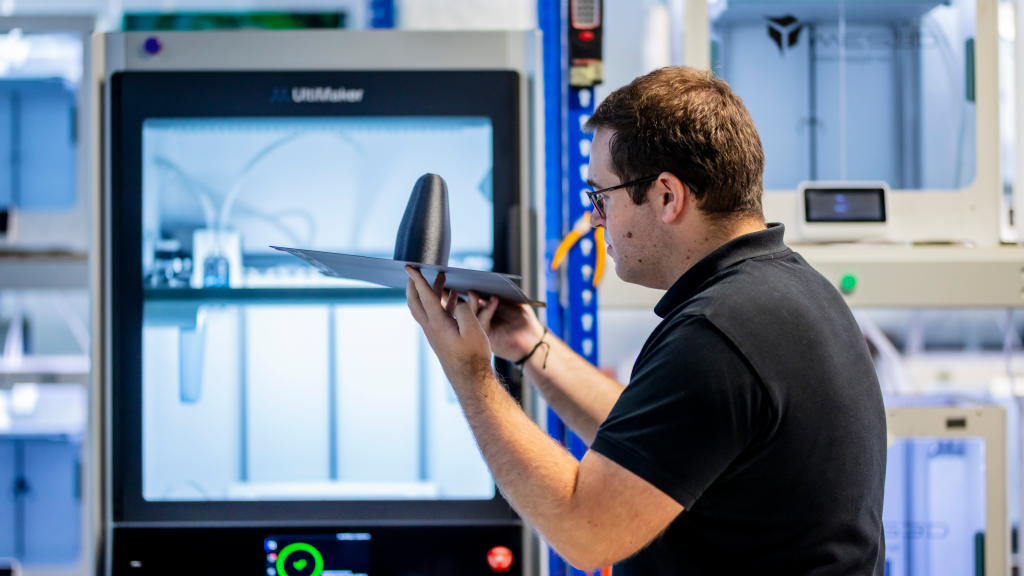

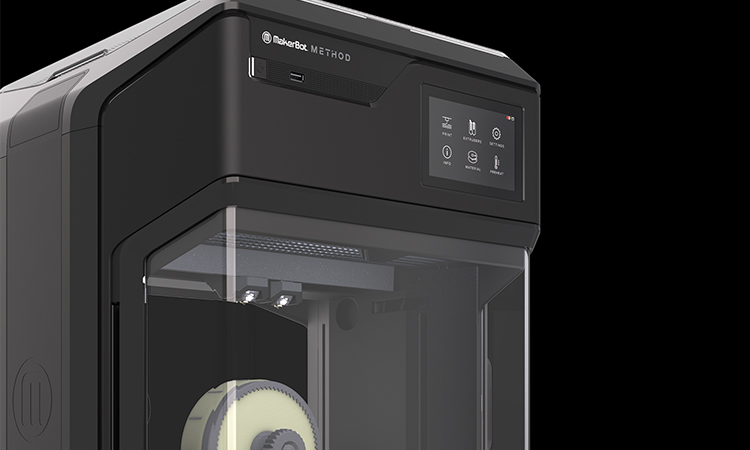

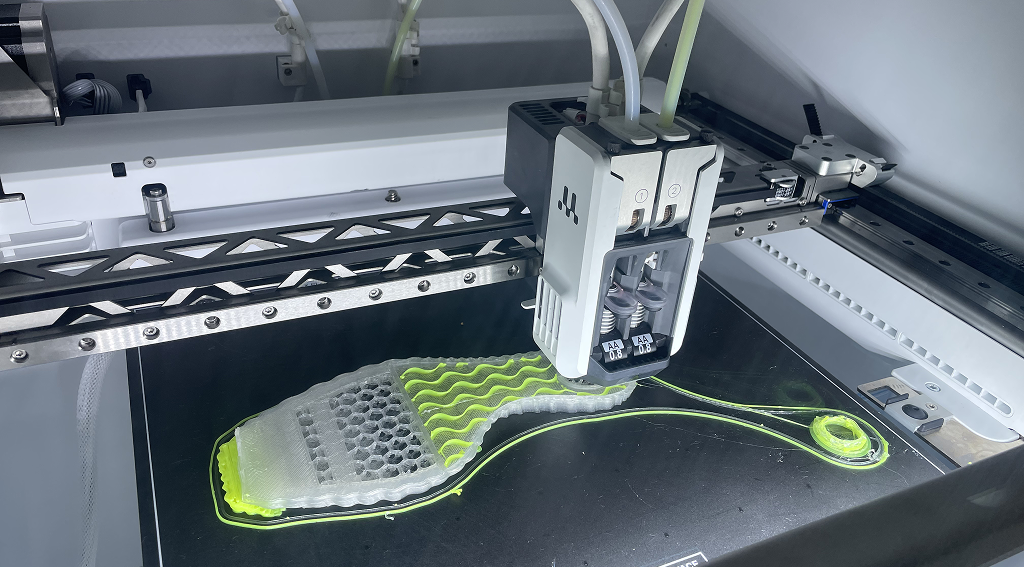

The Australian 3D printer market has a new disruptive player in the mix with the introduction of the MakerBot Method. It is a 3D printer that bridges the gap between desktop and industrial 3D printing. It brings the precision and reliability of rapid prototyping together with the accessibility of 3D desktop printing.

The Method was developed from the ground up by leveraging industry-leading Stratasys technologies combined with MakerBot’s accessibility and smart workflow features. The Method was built to accelerate product development, reducing production and labour costs and dramatically reducing the total cost of ownership.

MakerBot Method requires no technician or installation support, is up to 2x faster the desktop 3D printers and has a dimensional tolerance of +- 0.2mm. Featuring a circulated heated chamber, dual performance extruders and PVA water soluble support, it’s 1/3 the first-year cost of an entry-level industrial 3D printer.

As the sole distributor for MakerBot in Australia, we (Alloys) invited a hand-picked group of resellers to spend an afternoon learning about the new market opportunities the Method is forging and getting hands-on with the machines. The partners were given the opportunity to join an exclusive channel Partner Program specific to the professional 3D market: prototyping and manufacturing.

“We’re excited to bring the Method to Australia to give maximum innovation for minimal investment.” said Alloys CEO and MakerBot distributor in Australia, Paul Harman. “It’s an agile solution perfect for designers, engineers, product developers and innovators. We’re really looking forward to exploring the untapped opportunities that this specialist product will bring.”

For more information about MakerBot Method visit www.makerbot3d.com.au/3d/method/

If you are interested in becoming a partner, please contact Dave Guttmann directly to discuss the opportunity daveg@alloys.com.au or 03 9411 1813.