Industrial 3D Printing Just Got Easier

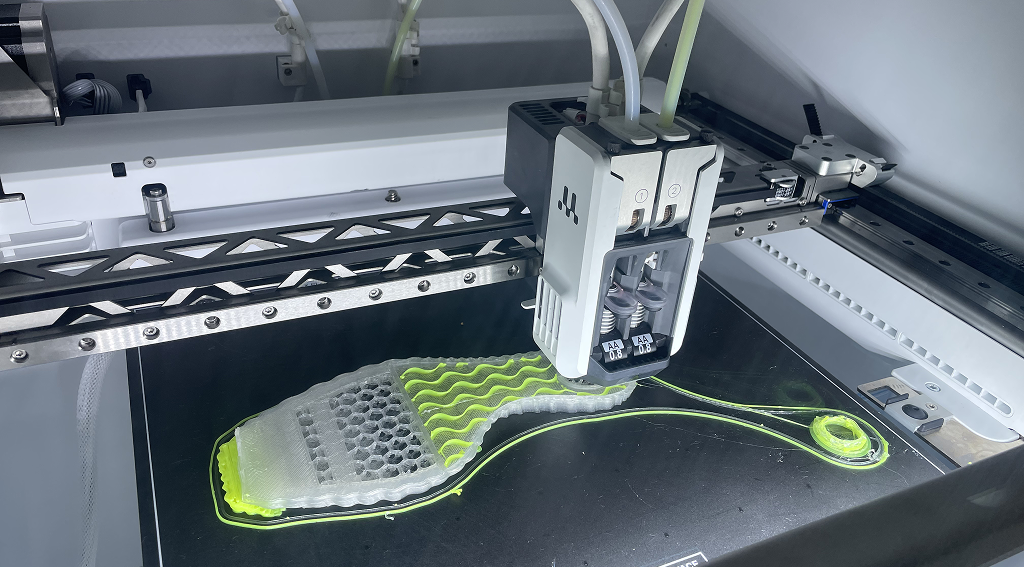

Experience easy 3D Industrial Printing with RapidRinse™ and ABS-R, two new 3D Printing materials for 2022 by MakerBot. These materials combine to simplify 3D printing with ABS polymer material by effectively streamlining workflow steps and reducing the need for more equipment and additional costs. Developed for high performance on the MakerBot METHOD X® and METHOD X Carbon Fibre 3D printers, the new MakerBot RapidRinse™ and ABS-R materials are suited to print a range of industrial applications to spec, from manufacturing tools to production parts.

RapidRinse™ Water Soluble Support

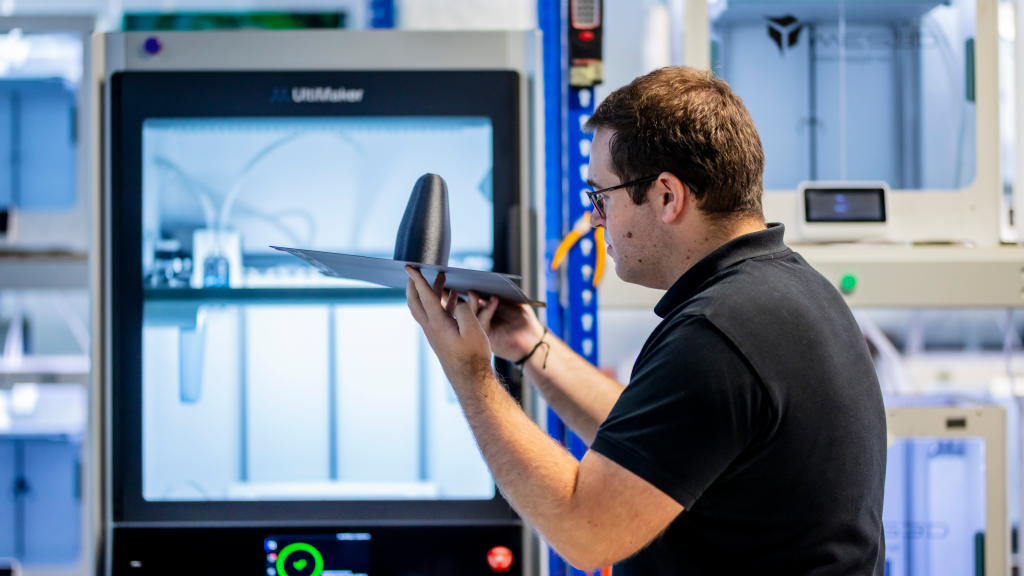

MakerBot RapidRinse™ is a tap water soluble support material for ABS, that dissolves easier, cleaner and faster than anything else. This game changing new material from MakerBot allows you to print ABS manufacturing tools and production parts to spec, with the ease of PLA. Requiring no caustic chemicals or solvents, it’s easier and safer to work with.

ABS-R For Superior 3D Printing and Performance

ABS is one of the most in-demand, yet difficult, materials to successfully print on a desktop 3D printer due to its propensity to shrink, warp, curl, or crack without the right conditions. ABS-R is a new ABS formulation that provides superior printing reliability and performance for consistent, repeatable ABS prototypes, tools, and parts. ABS-R is optimized to work with the new RapidRinse fast-dissolving support material to deliver the best print quality and user experience.

ABS as Easy as PLA with METHOD X

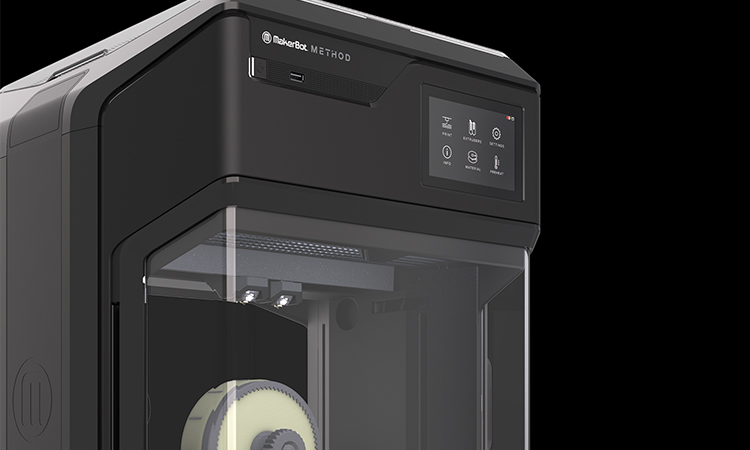

The METHOD X’s heated chamber, a patented VECT™ (Variable Environmental Controlled Temperature) 110 Technology, combined with RapidRinse™ soluble supports are designed to deliver incomparable ABS parts as easily as PLA but with superior material properties. Printing with RapidRinse on METHOD X can produce dimensionally accurate ABS parts of ±0.2mm (±0.007 inch)[2], giving engineers more confidence in creating parts to spec.

The addition of RapidRinse™ and ABS-R further strengthens METHOD X’s growing portfolio of advanced engineering-grade materials. MakerBot materials for METHOD are formulated to meet the highest standards. METHOD X can print the same polymers, composites, and metals found in familiar manufacturing processes—from injection moulding to machining—due to its unique environmental control features. Its 6-in-1 modular extruder platform also allows for a quick change between material groups, preventing cross-contamination and faster extruder degradation.

Available on METHOD X

Engineered and tested for over half a decade to print non-stop with over 15 patented technologies from Stratasys, METHOD X 3D printers are built to reliably deliver prototypes, parts, complex assemblies, and manufacturing aids with greater strength and dimensional accuracy.

For more information on RapidRinse™, ABS-R, or the METHOD X 3D Printer range, contact MakerBot Australia.