📊 New MakerBot Report: 74% Plan to Invest in 3D Printing in 2021

MakerBot’s inaugural 3D Printing Trends Report reveals mounting confidence in the power of 3D printing to transform business operations.

Nearly three-quarters (74%) of respondents say they plan to invest in 3D printing next year — and half expect to invest up to $100,000.

Despite COVID-19 impacting the operations of almost 70% of respondents, 56% said their investment plans for 3D printing haven’t changed. This reflects growing belief in 3D printing’s ability to boost resilience, responsiveness, and long-term profitability.

“These findings confirm what we have known for some time – and that is the potential of 3D printing to transform business operations,” said Nadav Goshen, CEO.

“When faced with the kind of challenges that businesses have had to contend with over the last 12 months, it is not unusual to see them cut all but the most critical capital expenditure. However, this is clearly not the case with 3D printing. While COVID-19 impacted the business operations of nearly 70% of the respondents, 56% said that it did not impact their investment plans in 3D printing. In fact, when respondents were asked what their investment plans were for next year, 74% stated that they still had plans to invest in 3D printing. This is an incredibly positive response which, we believe, signals growing confidence in 3D printing’s ability to improve resilience, responsiveness and, ultimately, the profitability of business operations," he continued.

Key insights from the report:

-

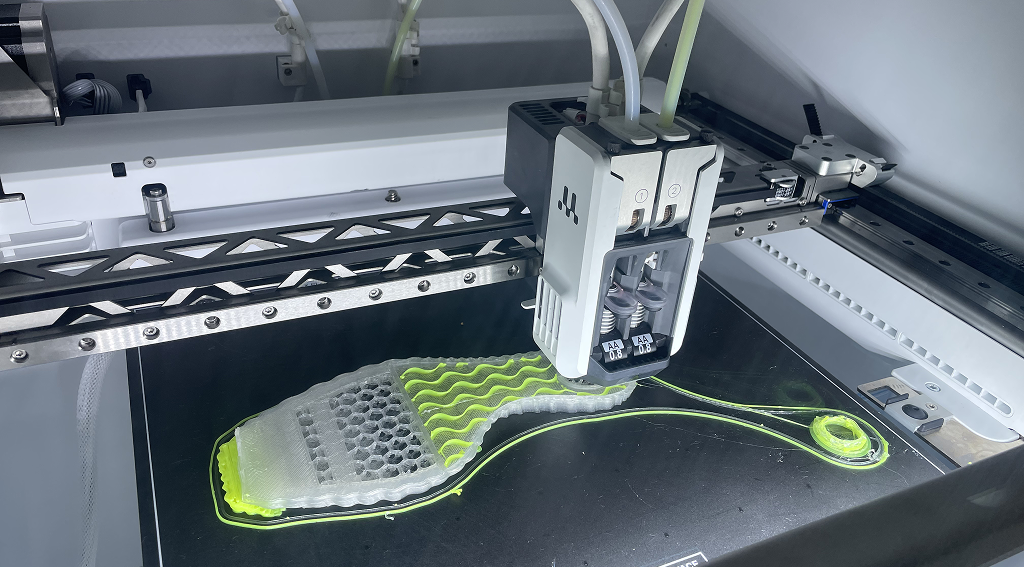

Customisation leads adoption

68% want the ability to create custom low–mid-volume parts, while 57% value the ability to print complex geometries. -

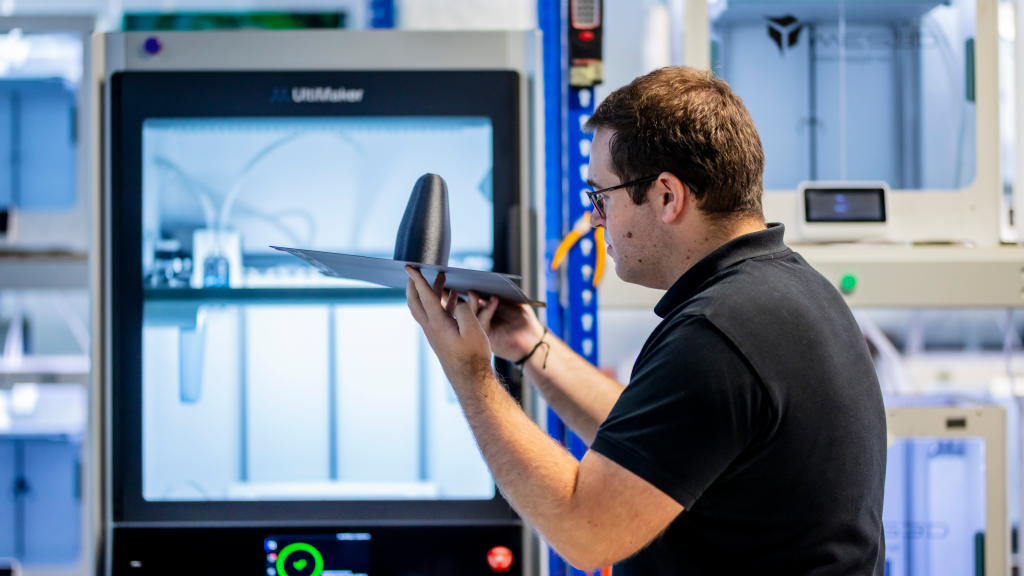

Still essential in R&D

Concept modelling (70%), functional prototypes (66%), and R&D (44%) remain top applications. -

Print quality matters most

Dimensional accuracy (61%) and reliability (65%) are the top factors when choosing a printer. -

FDM® dominates

77% use FDM/FFF printers, with plastics (93%) and resins (25%) as the main materials. -

Barriers remain

53% cite budget limitations, and 29% point to lack of technical expertise. -

Rapid development expected

In the next 3–5 years, 61% anticipate more material options, while 58% expect lower operating costs.

Nadav Goshen, CEO, says the findings reinforce 3D printing’s growing role in future-ready business operations — moving beyond prototyping and expanding rapidly into production.

ls to emerge, while 58% expect the cost of using the technology to decrease.

“We are pleased to release the MakerBot 3D Printing Trend Report, our first report on the trends and factors that are impacting the use of 3D printing. 3D printing has come a long way since the early days of the technology in the 1980s. But as the technology moves from prototyping to production, we expect to see the expansion of its use and applications continue to grow at an exponential rate. As a supplier, we believe it is our responsibility to look at these behaviours to better understand the needs of users and, thus, be able to deliver better products and services,” added Goshen.

Download the full report here: https://www.alloys.com.au/documents/Promotion2021/MakerBot3DPrintingTrendsReport.pdf